PRECESSION ELECTRON DIFFRACTION AND APPLICATIONS

Precession electron diffraction (PED) is a specialized method to collect electron diffraction patterns in a transmission electron microscope (TEM). By rotating (precessing) a tilted incident electron beam around the central axis of the microscope, a PED pattern is formed by integration over a collection of diffraction conditions. This produces a quasi-kinematical diffraction pattern that is more suitable as input into directmethods algorithms to determine the crystal structure of the sample.

OVERVIEW

Geometry

Precession electron diffraction is accomplished utilizing the standard instrument configuration of a modernTEM. The animation illustrates the geometry used to generate a PED pattern. Specifically, the beam tilt coils located pre-specimen are used to tilt the electron beam off of the optic axis so it is incident with the specimen at an angle, φ. The image shift coils post-specimen are then used to tilt the diffracted beams back in a complementary manner such that the direct beam falls in the center of the diffraction pattern. Finally, the beam is precessed around the optic axis while the diffraction pattern is collected over multiple revolutions.

The result of this process is a diffraction pattern that consists of a summation or integration over the patterns generated during precession. While the geometry of this pattern matches the pattern associated with a normally incident beam, the intensities of the various reflections approximate those of the kinematical pattern much more closely. At any moment in time during precession, the diffraction pattern consists of a Laue circle with a radius equal to the precession angle, φ. It is crucial to note that these snapshots contain far fewer strongly excited reflections than a normal zone axis pattern and extend farther into reciprocal space.

Thus, the composite pattern will display far less dynamical character, and will be well suited for use as input into direct methods calculations(Electron beam precession and applications /structure analysis)

[111] diffraction pattern of mayenite mineral (cubic a= 12.5 A) at different precession angles

Advantages

PED possesses many advantageous attributes that make it well suited to investigating crystal structures via direct methods approaches

1. Quasi-kinematical diffraction patterns: While the underlying physics of the electron diffraction (ED) is still dynamical in nature, the conditions used to collect PED patterns minimize

many of these effects. The scan/de-scan procedure reduces ion channeling because the pattern is generated off of the zone axis. Integration via precession of the beam minimizes the effect of non-systematic inelastic scattering, such as Kikuchi lines. Few reflections are strongly excited at any moment during precession, and those that are excited are generally muchcloser to a two-beam condition (dynamically coupled only to the forward-scattered beam).Furthermore, for large precession angles, the radius of the excited Laue circle becomes quite large. These contributions combine such that the overall integrated diffraction pattern resembles the kinematical pattern much more closely than a single zone axis pattern.

2. Broader range of measured reflections: The Laue circle (see Ewald sphere) that is excited at any given moment during precession extends farther into reciprocal space. After integration over

multiple precessions, many more reflections in the zeroeth order Laue zone (ZOLZ) are present, and as stated previously, their relative intensities are much more kinematical. This provides considerably more information to input into direct methods calculations, improving the accuracy of phase determination algorithms. Similarly, more higher order Laue zone (HOLZ) reflections are present in the pattern, which can provide more complete information about the three-dimensional

From left to right : [111] diffraction pattern of mayenite mineral (cubic a= 12.5 A) at different precession angles 0 mrad for complete dynamical ED pattern , 40 mradprecession angle for quasi-kinematical electron diffraction (ED) pattern.

Practical considerations

Precession electron diffraction is typically conducted using accelerating voltages between 100-400 kV.Patterns can be formed under parallel or convergent beam conditions. Most modern TEMs can achieve a tilt angle, φ, ranging from 0-3°. Precession frequencies can be varied from Hz to kHz, but in standard cases 100 Hz has been used.In choosing a precession rate, it is important to ensure that many revolutions of the beam occur over the relevant exposure time used to record the diffraction pattern. This ensures adequate averaging over the excitation error of each reflection. Beam sensitive samples may dictate shorter exposure times and thus, motivate the use of higher precession frequencies.

One of the most significant parameters affecting the diffraction pattern obtained is the precession angle, φ. In general, larger precession angles result in more kinematical diffraction patterns, but both the capabilitiesof the beam tilt coils in the microscope and the requirements on the probe size limit how large this angle canbecome in practice. Because PED takes the beam off of the optic axis by design, it accentuates the effect of

the spherical aberrations within the probe forming lens. For a given spherical aberration, Cs, the probe diameter, d, varies with convergence angle, α, and precession angle, φ, as(Electron beam precession and applications /structure analysis)

Thus, if the PED angle is quite small (<1°) , the maximum spot broadening will be restrained. The maximum beam broadening can be at high precession angles (>2 °), but can be limited in Cs corrected instruments.In principle the effective precessed probe (at PED angles>30 mrad) is typically ~10-50x larger than the un-precessed one, due to uncontrolled aberrations present at high angles of tilt. However, in Digistar Precession unit there is possibility for automatic “beam broadening compensation” corrections (through Topspin acquisition software)that can reduce effectively by a factor of x 5 the PED beam size that is enlarged at higher angles.

If the precession angle is made too large, further complications due to the overlap of the ZOLZ and HOLZ reflections in the projected pattern can occur. This complicates the indexing of the diffraction pattern and can corrupt the measured intensities of reflections near the overlap region, thereby reducing the effectiveness of the collected pattern for direct methods calculations.

(from left to right) Typical spot size (200 kV TEM) at 0° precession angle (real spot size 23 nm maginification x 1000.000) , Beam broadening and deformation at 1° precession angle (circle diameter 155 nm), (right) Beam broadening at 1° precession angle after beam compensation (beam diameter 34 nm) GUI of Topspin software enabling automatic compensation of beam broadening due to precession

Theoretical considerations

While it is clear that precession reduces many of the dynamical diffraction effects that plague electron diffraction, the resulting patterns cannot be considered purely kinematical in general. There are models that attempt to introduce corrections to convert measured PED patterns into true kinematical patterns that can be used for more accurate direct methods calculations, with varying degrees of success. In purely kinematical diffraction, the intensities of various g reflections ![]() ,are related to the square of the amplitude of the structure factor Fg by the equation :

,are related to the square of the amplitude of the structure factor Fg by the equation :

![]()

More complete and accurate treatments of these theoretical correction factors have been shown to adjust measured intensities into better agreement with kinematical patterns. Only by considering the full dynamical model through multislice calculations can the diffraction patternsgenerated by PED be simulated. However, this requires the crystal potential to be known, and thus is mostvaluable in refining the crystal potentials suggested through direct methods approaches. The theory ofprecession electron diffraction is still an active area of research, and efforts to improve on the ability tocorrect measured intensities without a priori knowledge are ongoing.

Historical Development

The first precession electron diffraction system was developed by Vincent and Midgley in Bristol, UK and published in 1994 (ref) Preliminary investigation into the Er2Ge2O7 crystal structure demonstrated the feasibility of the technique at reducing dynamical effects and providing quasi-kinematical patterns that could be solved through direct methods to determine crystal structure.Over the next ten years, a number of university groups developed their own precession systems and verified the technique by solving complex crystal structures, including the groups of J. Gjonnes (Oslo), Migliori (Bologna), and L. Marks, C.Own (Northwestern) (Electron beam precession and applications /structure analysis)

In 2004, NanoMEGAS developed the first commercial procession system capable of being retrofit to most modern TEM. This hardware solution enabled more widespread implementation of the technique and spurred its more mainstream adoption into the crystallography community. As of 2020, more than 500 publications (Electron beam precession and applications /structure analysis) have relied on the technique tosolve or corroborate crystal structures; many on materials that could not be solved by other conventional crystallography techniques like X-Ray diffraction. NanoMEGAS precession systems are actually installed and used in more than 180 laboratories across the world.

Extending TEM capabilities with Scanning Precession Electron Diffraction (PED)

Dr. Jing Lu, Application scientist NanoMEGAS USA

In this webinar, Dr. Jing Lu will explain how modern TEM microscopes benefit from PED, a breakthrough in electron crystallography, now commonly used for synchronized scanning and precession (4D-STEM). In this presentation we will show how the NanoMEGAS system provides streamlined PED acquisition with automated precession alignments and analysis featuring ASTAR orientation /phase mapping and Topspin strain mapping while achieving high spatial resolution and precision

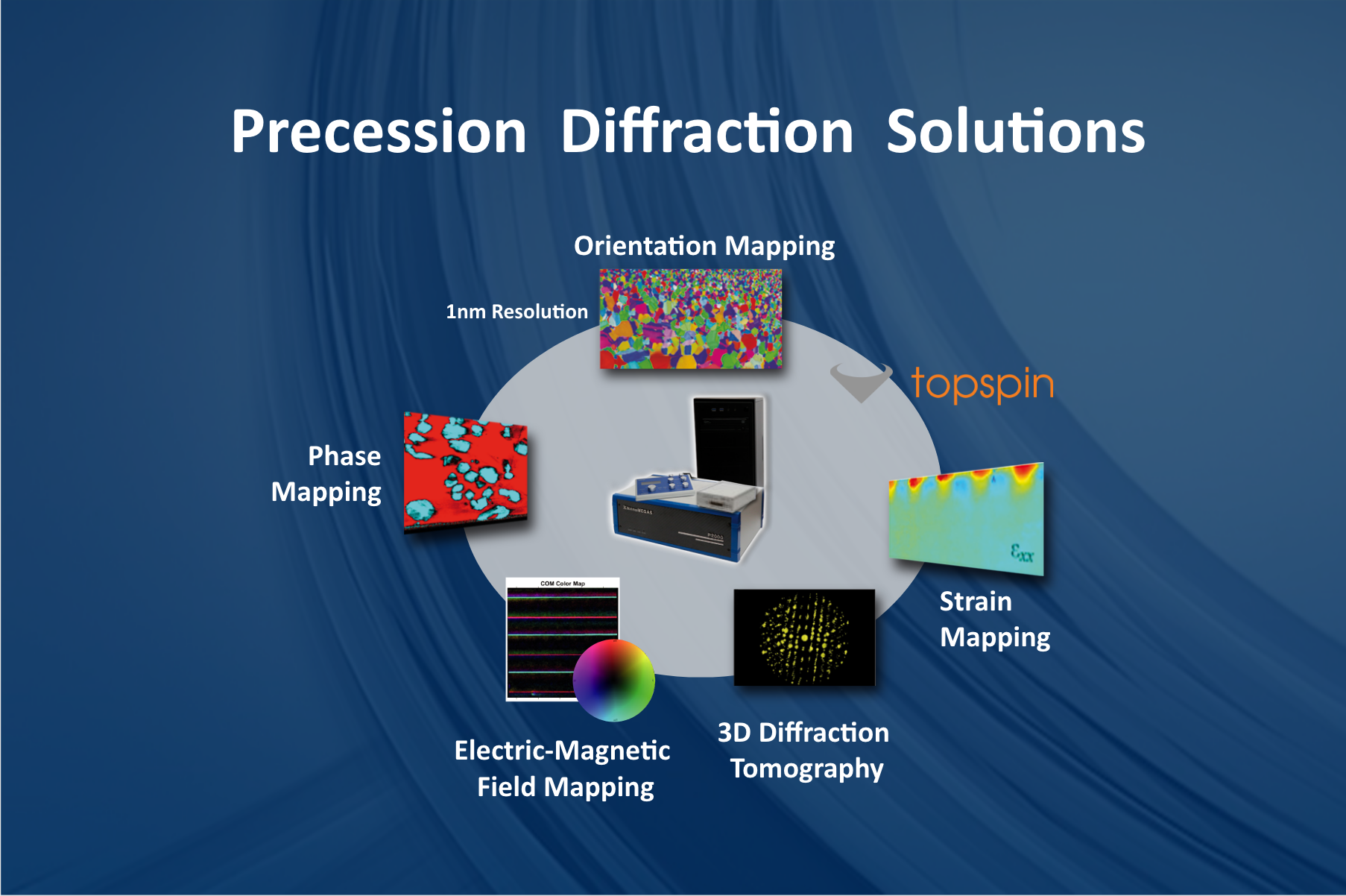

PRECESSION DIFFRACTION APPLICATIONS

TEM Orientation & phase mapping (ASTAR)

Mapping the relative orientation of crystalline grains and/or phases helps understand material texture at the micro and nano scales. In a transmission electron microscope, this is accomplished by recording a diffraction pattern at a large number of points (over a region of the crystalline specimen. ED/PED spot patterns are collected sequentially with a dedicated external (CCD) camera while the sample area (that is typically tens of square micrometers) is scanned by the primary electron beam and simultaneously precessed around the optical axis of the microscope. The tool named “ASTAR“(automatic TEM phase-orientation mapping) includes precession device “DigiSTAR“The external dedicated “fast” CCD camera (8 bit, > 150 frames/s, 250 x 250 pixels image size) is mounted in front of the TEM screen.

By comparing the recorded patterns to a database of known patterns (simulated patterns of existing known phases), the relative orientation of grains in the field of view can be determined.

Because this process is highly automated, the quality of the recorded diffraction patterns is crucial to the software’s ability to accurately compare and assign orientations and/or crystal phases to each pixel. Thus, the advantages of PED are well-suited for use with this scanning technique. By recording a PED pattern at each pixel, dynamical effects are reduced, and the patterns are more easily& precisely compared to simulated data, improving the accuracy of the automated phase/orientation assignment.

For a typical map of 500×500 pixels, beam scanning (and precessing) over the sample area may take only 5-10 minutes. Comparison with simulated templates can be done off-line andmay take about 5 minutes for highly symmetric cubic materials and 3-6 times longer for unit cells with lower symmetry as more templates must be generated. Template generation is done on the basis of inputs of the crystal structure parameters of the known phases (for with the spatial distribution is to be mapped) to the software. Typical mapped areas are of the order of 5x 5 microns; spatial resolution is about half the primary electron beam size, e.g. 10 nm for 20 nm spot size of a TEM/LaB6 and can be as small as 1 nm for TEM- FEG microscopes.

Phase identification is done with cross-correlation and statistical match of experimental ED/PED pattens with generated ED templates of all possible (known) phases. Using scanning and precession modes in ASTAR also generates PED patterns with FOLZ reflections visible and this helps to distinguish “subtle” differences between structures with same crystal cell parameters and symmetry, but different space groups (example mayemite-magnetite crystals.

Again,it is important to stress that ASTAR-DigiSTAR can be retrofitted to any TEM (also the dedicated CCD camera can be transferred from one TEM to another) .

Schematics of the ASTAR beam scanning mode combined with precession diffraction (a), beam scanning over the sample (b) and generation of ED (c) or PED (d) patterns ; generation of simulated ED templates (e)

Strain mapping analysis

In modern transistor devices strain monitoring is critical for process development. Strain metrology on these devices demand a high degree of accuracy, precision and efficiency in data acquisition. At the scale of these devices, strain measurement using transmission electron microscope (TEM) is the only approach that can provide the adequate spatial resolution.

Existing TEM methods to measure strain include convergent beam electron diffraction (CBED), dark field electron holography, high resolution imaging and nanobeam diffraction (NBD). Although CBED is an accurate way to measure strain, the sample needs to be relatively thick (>150 nm) which limits its applicability to semiconductor devices. Dark field holography is another attractive approach although the experimental difficulties limits its application as a strain metrology technique. High resolution imaging offers the best spatial resolution for strain measurement. However, the sample needs to be ultra thin with uniform thickness and no bending. This stringent requirement along with limited field of view makes it difficult to use high resolution imaging for routine strain analysis.

Of these techniques, NBD is the most practical approach with good spatial resolution and ease of implementation. Hence NBD has been adopted widely in the industry for strain metrology. Strain measurement using NBD involves measurement of shift in individual diffraction spots. However, the presence of strong dynamical effects in electron diffraction is a serious limitation to achieve the desired precision. Since strain is measured using NBD patterns that are exactly on zone axis, the dynamical effects are exacerbated. Because of the dynamical effects, spot intensity distributions are strongly dependent on local specimen thickness and orientation.

Although the technique is straightforward, it requires tedious specimen tilting to align specimen exactly at the zone axis. Figure below compares two Si diffraction patterns from near by regions in the same specimen prepared by focused ion beam milling.

(Left) Si <110> Diffraction patterns from two nearby regions in a FIB sample. Note the strong intensity variations due to dynamical effects.(Right)Si <110> Diffraction patterns from the same region as shown in Fig. 1 with 1∘precession.

Topspin strain analysis is a novel approach to strain measurement that combines NBD with precession electron diffraction to overcome the above mentioned limitations. Further, Topspin strain analysis uses a robust analysis algorithm for high accuracy and precision with the ability to handle overlapping patterns.

Precession offers the following advantages for strain measurement:

-Dynamical effects are reduced even when the specimen is close to zone axis. Because of this diffraction patterns are less sensitive to changes in thickness

-The use of precession also enables the collection of higher order reflections which are more sensitive to small variations in strain

-Zone axis alignment is easier with precession as the averaging of diffraction patterns over different tilts results in a symmetric diffraction pattern even when the specimen is slightly off axis.

-Effect of specimen bending is mitigated with precession.

Topspin strain analysis uses a proprietary algorithm to identify all the spots from the crystal of interest with the desired orientation. For most Si devices, this is the <110> zone axis pattern of Si. The algorithm uses a model based approach to accurately find the spot positions for both thereference and the strain diffraction patterns.

Topspin hardware consists of Digistar , which enables synchronized beam scanning with precession. Topspin system can be installed on most modern microscopes and it does not require a scanning unit to be present on the microscope. Topspin has a streamlined workflow which makes it possible to acquire strain data sets with minimal time for set up. In a typical Topspin set up typical precession angle is of 1∘, acquisition time for 150 x 150 map is 5-10 min, typical strain analysis time is 5 to 10 min.

BEYONG DIFFRACTION- 3D PRECESSION IMAGE TOMOGRAPHY

Although the PED technique was initially developed for its improved diffraction applications, theadvantageous properties of the technique have been found to enhance many other investigative techniques in the TEM. These include bright field and dark field imaging, electron image tomography, and composition-probing techniques like energy-dispersive x-ray spectroscopy (EDS) and electron energy loss spectroscopy (EELS).

3D image tomography

Though many people conceptualize images and diffraction patterns separately, they contain principally thesame information. In the simplest approximation, the two are simply Fourier transforms of one another. Thus, the effects of beam precession on diffraction patterns also have significant effects on the corresponding images in the TEM. Specifically, the reduced dynamical intensity transfer between beams that is associated with PED results in reduced dynamical contrast in images collected during precession of the beam. This includes a reduction in thickness fringes, bend contours, and strain fields.While these features can often provide useful information, their suppression enables a more straightforward interpretation of diffraction contrast and mass contrast in images.

In an extension of the application of PED to imaging, electron tomography can benefit from the reduction of dynamic contrast effects. Tomography entails collecting a series of images (2-D projections) at various tilt angles and combining them to reconstruct the three dimensional structure of the specimen. Because many dynamical contrast effects are highly sensitive to the orientation of the crystalline sample with respect to the incident beam, these effects can convolute the reconstruction process in tomography. Similarly to single imaging applications, by reducing dynamical contrast, interpretation of the 2-D projections and thus the 3-D reconstruction are more straightforward.

Difficulties in 3D defect reconstruction includes thickness fringes, bend contours and strain fields related contrast .Using the combination of both tomography and precession techniques in the TEM microscope it is possible to obtain projections less affected with dynamical contrast . Electron beam precession in BF TEM mode leads to from quasi-two beams to strong two beams condition and extinction of bend contours related contrast. The viability of the combination of these two techniques has strong potential for defect reconstruction in BF-DF-TEM applications as an alternative to STEM-HAADF.

Bright field TEM tomography acquisition combined with beam precession (alternatively on/off) : Al thin foil with Sn precipitates, tilt series: +49° > a > -61°, angle step: 2°, Precession angle: 0.6° , magnification 25.000 x (Jeol 2100 -DigiSTAR ) courtesy Rebled, Yedra,Portillo, Estrade, PeiroUniv Barcelona (Spain)

4D-Scanning Precession Electron Diffraction (4D-SPED) acquisition method in TEM, is currently used in several applications for materials analysis like Orientation & Phase mapping and Strain analysis [1]. 4DSPED is an extension of 4D-STEM technique and it consists in scanning the electron beam over the structure to observe and record at each position a Precession Electron Diffraction Pattern (PED) pattern.

4D-SPED acquisition together with data processing dedicated software is applied to characterize in detail local electric/magnetic fields and built-in potentials in functional materials.

During scanning over the sample, the transmitted beam is deflected though the local electric field by the Lorentz force.

The module of the local electric field translates into the shift of the intensity distribution in the transmitted central electron beam.

Electric filed is relying on COM (center of mass) displacement of the illumination intensity. Beam Precession of 0.1-0.4 degrees is used to get rid of dynamical effects and obtain ED patterns with less noise leading to enhanced results.

Electric field calculations are of high interest to study properties of many materials and devices, e.g. transistors, solar cells or sensors, nanowires, batteries, etc.

Data can be collected by scanning over the area of interest with a pseudo-parallel beam within size of 0.7- 1.5nm (TEM dependent), using small Condenser aperture (~10μm) and convergent angle that can typically vary from 0.5 mrad to 5mrad (or more) with step size equal or half of the probe size, to achieve highest possible spatial resolution (down to 1nm).

The camera length is properly adjusted to visualize properly the transmitted beam (000) displacement.

Beam convergence angle and camera length are related parameters to fit the beam onto the detector window. Data can be collected either by standard NanoMEGAS external Stingray CCD, or by triggering/synchronizing with high-end direct detection /CMOS cameras (like Gatan, QD, ASI , Dectris or PnCCD detectors) by NanoMEGAS dedicated scan generator.

The primary goal of crystallography is to determine the three dimensional arrangement of atoms in a crystalline material. While historically, x-ray crystallography has been the predominant experimentalmethod used to solve crystal structures ab-initio, the advantages of precession electron diffraction make it one of the preferred methods of electron crystallography.

Unit cell symmetry determination

The symmetry of a crystalline material has profound impacts its emergent properties,

including electronic band structure, electromagnetic behavior, and mechanical properties . Crystal symmetry is described and categorized by the crystal system, lattice, and space group of the material. Determination of these attributes is an important aspect of crystallography.

Precession electron diffraction enables much more direct determination of space group symmetries over other forms of electron diffraction. Because of the increased number of reflections in both the zero order Laue zone and higher order Laue zones, the geometric relationship between Laue zones is more readily determined. This provides three-dimensional information about the crystal structure that can be used to determine its

space group.(Electron beam precession and applications /Space group determination )

Furthermore, because the PED technique is insensitive to slight misorientation from the zone axis, it provides the practical benefit of more robust data collection.

ATLAS OF ELECTRON DIFFRACTION ZONE-AXIS PATTERNS

Prof. J.P Morniroli Univ of Lille (France) FREE DOWNLOAD (Atlas + several lectures on Precession Diffraction) www.Electron-Diffraction.fr

Ab-initio structure determination

Diffraction patterns collected through PED often agree well-enough with the kinematicalpattern to serve as input data for direct methods calculations. A three-dimensional set of intensities mapped over the reciprocal lattice can be generated by collecting diffraction patterns over multiple zone axes. Applying direct methods to this data set will then yield probable crystal structures. Coupling direct methods results with simulations (e.g. multislice) and iteratively refining the solution can lead to the ab initio determination of the crystal structure.

direct methods results with simulations (e.g. multislice) and iteratively refining the solution can lead to the ab initio determination of the crystal structure.

The beam precession technique has been used to determine the crystal structure of many classes ofmaterials. Initial investigations during the emergence of the technique focused on complex oxidesand nano-precipitates in Aluminum alloys that could not be resolved using x-ray diffraction.Since becoming a more widespread crystallographic technique, many more complex metal oxide structures have been solved.(Electron beam precession and applications /structure analysis)

Zeolites are a technologically valuable class of materials that have historically been difficult to solve using x-ray diffraction due to the large unit cells that typically occur. PED has been demonstrated to be a viable alternative to solving many of these structures, including the ZSM-10, MCM-68, and many of the ITQ-n class of zeolite structures.PED also enables the use of electron diffraction to investigate beam-sensitive organicmaterials.Several structures could be solved ab-initio using that approach such as minerals, catalysts ,complex oxide structuresand organic compounds(pharmaceuticals and proteins) .(Electron beam precession and applications /biology-organics).In all cases structure solution from PED data set clearly revealed all heavy and most of light atom positions like oxygens; attempts using conventional ED data sets were unable to provide any structure solution.

STRUCTURAL ELECTRON CRYSTALLOGRAPHY

Douglas Dorset PLENUM PRESS 1995, ISBN 0-306-45049-6

Electron Microscopy and Electron Diffraction

Authors:Xiaodong Zou, Sven Hovmöller and Peter OleynikovOxford University Pres

3D electron diffraction tomography (Micro-ED)

3D electron diffraction tomography approach has been developed by U.Kolb (3D diffraction tomography/instrumentation and techniques)and named asautomated diffraction tomography (ADT); 3D hkl precession data are acquired through sequentially tilting a selected nanocrystal around an arbitrary crystallographic axiswith a variable tilt step down to 1° through the maximum TEM tilting range (usually from -45° to + 45°). Such a data set contains nearly all reflections present in the covered wedge of the reciprocal space.The advantage of 3D electron diffraction tomography data collection over individual ZA collection is that data collection can begin from any arbitrary (non-oriented) section of reciprocal space without any prior knowledge of the crystal cell ;

after collection of typically 90 reciprocal space sections with single-tilt TEM holder , 3D reciprocal cell can be reconstructed automatically, crystal cell can be accurately determined (2-5% error) and 3D intensities can be measured to provide full 3D structure solution . 3D data acquisition can be done manually or automatically in some TEM platforms ; STEM Automated diffraction tomography (ADT) acquisition in nanobeam mode is especially effective for data collection from beam sensitive materials because it uses low dose illumination.

(ADT) uses software to collect diffraction patternsover a series of serial tilt increments(variable tilt step down to 1°) or in continuous tilt mode (Micro-ED)( 3D diffraction tomography/instrumentation and techniques); in this way, the generated3D(tomographic) data set of reciprocal lattice intensities can be used for structure determination. By coupling this technique with beam precession , the range and quality of the data set can be greatly improved.The combination of ADT-PED has been employed effectively to investigate complex framework structuresand beam-sensitive organic crystals., even protein crystals.( 3D diffraction tomography/proteins /organics-pharmaceuticals). Combining beam precession with dynamical refinements, it is possible to reveal Hydrogen atoms in the structure and even determine the absolute structure condiguration (3D diffraction tomography/proteins /absolute configuration .

Reconstructed three dimensional reciprocal space

showing hexagonal cell (P63/mmc a= 0.396nm, c =0.536 nm) for NiTenanocystal with data resolution up to 0.8A. Data have been collected from 80 precession diffraction patterns (precession angle 17 mrad) from -40° + 40° onTecnai 30- FEG-STEM DigiSTAR (courtesyDr.E.Mugnaoili, Dr.U.Kolb Mainz Univ)

Investigating composition

Energy-dispersive x-ray spectroscopy (EDS) and electron energy loss spectroscopy (EELS) are commonly used techniques to both qualitatively and quantitatively probe the composition of samples in the TEM. A primary challenge in the quantitative accuracy of both techniques is the phenomenon of channelling.

Put simply, in a crystalline solid, the probability of interaction between an electron and ion in the lattice dependsstrongly on the momentum (direction and velocity) of the electron. When probing a sample under diffraction conditions near a zone axis, as is often the case in EDS and EELS applications, channelling can have a large impact on the effective interaction of the incident electrons with specific ions in the crystal structure. In practice, this can lead to erroneous measurements of composition that depend strongly on the orientation and thickness of the sample and the accelerating voltage. Since precession diffraction entails an integration over incident directions of the electron probe, and generally does not include beams parallel to the zone axis, the detrimental channeling effects outlined above can be minimized, yielding far more accurate composition measurements in both techniques